LJideals-Adapter development and production process

Development process:

- First, according to the needs of users, the design is carried out. After the determination is made, the mold is opened and the outer casing is produced.

- Secondly, according to the performance requirements, the electronic engineer develops the electronic circuit part, selects the appropriate scheme, designs the electronic schematic diagram, and draws the drawing of the circuit board (PCB), and gives the PCB board manufacturer a sample of the PCB.

- Next, the electronics engineer makes a manual sample and then performs various tests such as performance testing, assembly testing, and aging testing on the sample.

- Then, the sample is tested after ok. Develop PCB production molds. Conduct small batch trial production. Testing will have some problems in the production process. Then make the appropriate adjustments.

- Finally, the circuit board (PCB) is finalized, and if the PCB changes, the mold needs to be reopened. Produce corresponding documents such as specifications, work instructions, and inspection instructions.

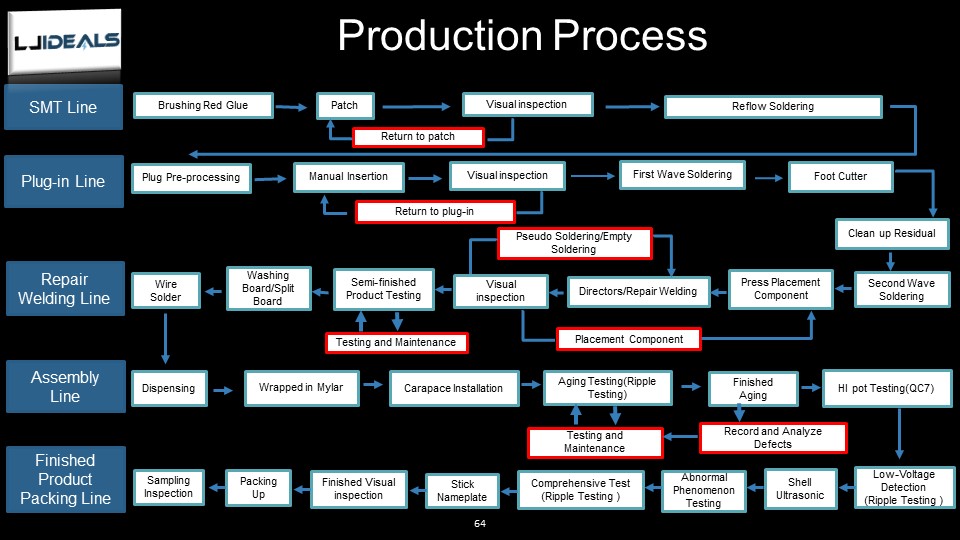

Mass production process:

1. SMT (SMT): After the materials are ready after the inspection is passed, the PCB is first passed through the SMT machine for the placement process;

2, The plug-in (DIP):

A good piece of PCB, pulled on the plug-in, the plug-in process. DIP will be subdivided into inserts, press parts, immersion tin, cutting electronic feet and other processes;

3, After welding (supplement welding):

In the plug-in pull, after immersing the circuit board after tin, some electronic components have not been on the good tin, this time you need to be welded to solve. The post-welding process is subdivided into:

Over-wave soldering: After the plug is pulled again by the machine, there is no good in metal material when immersed in tin;

Kanban repair welding: usually a PCB sub-area, many people carry out manual kanban, no good tin, manual repair, there are few electronic components, not inserted, also marked;

Replacing electronic materials: electronic materials are inserted in reverse, and fewer parts are corrected;

QC Test 1: The bare board is tested by making matching test tools, and the test is passed to the next process. If the test fails, return to the repairman for repair;

4, Assembly:

This process is the most and most complex, and is also an important process to test the level of adapter production technology.

- Bonding wire: Solder the DC wire to the bare board. Weld the AC wire to the lower case metal part of the case.

- Gluing: Gluing components that are easy to fall off or break during transportation.

- It has solder joints such as transformers, filters, AC lines, and DC lines.

- Enclosure: Close the outer casing of the switching power adapter.

- QC Test 2: Test the performance of each output through the computer integrated tester. If it does not pass, it will be handed over to the repairman for repair. Test again until you pass the test.

- Repair: Repair the switching power adapter that failed the test.

- Screw: Fix the outer casing. Some housings use ultrasonic waves. Just put it behind the i.QC test 3 process;

- Aging test: Transfer the screwed product to the aging workshop, carry out the aging test, and after the aging test for a certain period of time, transfer it back to the assembly and pull it to do the final full inspection QC test.

- QC Test 3: The last full inspection, the product after the aging test is fully inspected, if not passed, it is returned to e. Repair. Pass the test to the next step.

- Ultrasonic: If the outer casing is fixed with screws, this process is not required.

- Appearance QC: Here you need to pick out the appearance of the problem, replace the shell.

- Post nameplate: After the appearance inspection is passed, the product will be labeled accordingly.

- Packing: After the product passes the layer inspection, the finished product is packaged.

5. Quality sampling:

The finished products that have been completed shall be inspected according to the relevant national quality inspection standards. The sampling contents include functionality, appearance, and the like. After passing the sampling inspection of the quality department, it can be shipped.